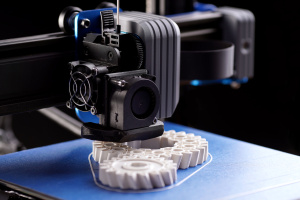

Additive manufacturing, also known as 3D printing, is a process of creating a three-dimensional object by depositing and joining successive layers of plastic material until the desired shape is achieved. Additive manufacturing has become a game-changer in various industries, offering significant advantages, including customizability, speed, and efficiency.

Additive manufacturing, also known as 3D printing, is a process of creating a three-dimensional object by depositing and joining successive layers of plastic material until the desired shape is achieved. Additive manufacturing has become a game-changer in various industries, offering significant advantages, including customizability, speed, and efficiency.

It is widely used in various industries and applications, such as aerospace and defense, where it is used to produce lightweight and strong components for spacecraft and aircraft. In the medical field, 3D printing is used to produce prosthetics, implants, and other medical devices that are customized to meet the needs of individual patients.

Additionally, 3D printing is used in the production of consumer goods, such as toys, phone cases, and kitchen utensils, among others. The technology is also used for prototyping and testing, as well as in the creation of art and architecture. The uses of 3D printing continue to evolve and expand as the technology advances.

Filament precision can have a huge impact on how well a 3D Printer operates. Providing a tight OD tolerance as well as consistent ovality can also prevent costly printer jams and uneven printing quality.

Better quality filament produces stronger prints that simply look better. With tolerances on 1.75 mm filament ranging from 0.05 mm down to as tight as 0.02 mm and on 2.85 mm from 0.10 mm down to 0.05" mm, AP offers the absolute best quality in the industry.

Advantages of Additive Manufacturing:

Uses of Additive Manufacturing:

Types of plastics:

AP can use a wide range of plastics as the building material. Some of the most commonly used plastics are Acrylonitrile Butadiene Styrene (ABS), Polylactic Acid (PLA), Nylon, Polyethylene and Polycarbonate (PC). Each of these plastics has its own unique properties and is used in different applications based on the specific requirements of the product. Additional additives such as carbon fiber and glass filled can also be added to these materials to enhance their properties depending on what would be needed for your application.

For those looking for more specialized filaments, there are options like TPU (Thermoplastic Polyurethane) and PVA (Polyvinyl Alcohol). TPU filament is a flexible material that is often used for creating soft and elastic objects such as phone cases, shoe soles, and medical devices. PVA filament, on the other hand, is a water-soluble material that is used as a support structure for complex prints. It can be dissolved in water, leaving behind the final printed object.