Nylon medical tubing has revolutionized the way medical professionals are able to provide care for their patients. This versatility and durability of this tubing make it an ideal choice for a wide variety of applications in the medical world and beyond.

Nylon medical tubing has revolutionized the way medical professionals are able to provide care for their patients. This versatility and durability of this tubing make it an ideal choice for a wide variety of applications in the medical world and beyond.

It's lightweight, strong, and flexible nature make it an ideal material for a variety of medical applications. A nylon tube has excellent resistance to abrasion and chemicals, ensuring that it will last for years of use.

The use of nylon medical tubing is especially beneficial in the areas of anesthesia delivery, drug delivery, and fluid management. It is also ideal for delivering fluids to patients, as it is able to easily and securely connect to other components of the medical system. This makes it an essential tool for medical professionals who need to provide efficient and effective care for their patients.

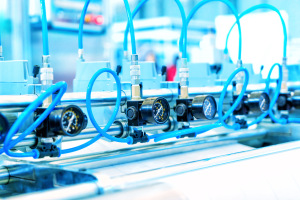

Nylon plastic tubing can also be used in other non-med applications. For example, Nylon pipe can be used in the pneumatics industry, while nylon air brake tubing is commonly used in the automotive industry.

Nylon medical tubing is also incredibly useful in surgeries. It can be used to create a secure connection for surgical instruments and other tools, allowing for easier and more precise procedures. It can also be used to ensure proper positioning of the instruments during a procedure, helping to ensure that the patient receives the best possible care.

Nylon medical tubing is also incredibly useful in surgeries. It can be used to create a secure connection for surgical instruments and other tools, allowing for easier and more precise procedures. It can also be used to ensure proper positioning of the instruments during a procedure, helping to ensure that the patient receives the best possible care.

Extruded nylon using different grades of nylon material can be selected with the most popular being Nylon 6/6, Nylon 11 and Nylon 12 tubing. Popular sizes include 4 mm and 6 mm dimensions.