Some tubing applications require a solid construction without the need for an inside diameter. This adds rigidity and strength when needed in certain applications. It also allows the ability to machine it, and most materials will have excellent chemical resistance.

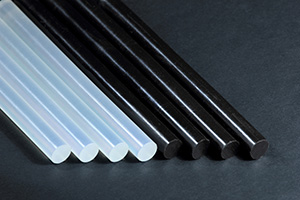

While most extruded plastic rod is round, it can also come in other shapes. This can include oval, square, rectangular and star as well as shapes that involve custom radiuses.

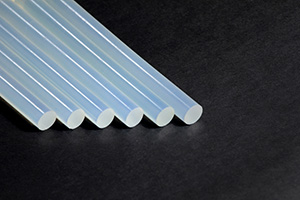

A.P. Extrusion, Inc. can custom extrude plastic rods into various materials. The appropriate material selection can be critical to the application it is used in. Polyethylene, polypropylene, and PVC rods are excellent for fabricating and welding. Polycarbonate extruded plastic rod is clear and has outstanding impact resistance and is still easy to machine. ABS and various nylons are stiff and offer great abrasion resistance and can be an excellent replacement for metal bearings and brushes. Custom blended materials can also be requested that can include fillers.

A.P. Extrusion, Inc. can custom extrude plastic rods into various materials. The appropriate material selection can be critical to the application it is used in. Polyethylene, polypropylene, and PVC rods are excellent for fabricating and welding. Polycarbonate extruded plastic rod is clear and has outstanding impact resistance and is still easy to machine. ABS and various nylons are stiff and offer great abrasion resistance and can be an excellent replacement for metal bearings and brushes. Custom blended materials can also be requested that can include fillers.

Extruded plastic rods are incredibly versatile and can be used in a wide range of applications. Industries included but not limited to are medical, automotive, and electrical to construction and DIY projects.

In the medical field, extruded plastic rods are used in devices and equipment. Their biocompatibility and ease of sterilization make them suitable for medical applications.

In the automotive industry, plastic rods are used in various components, including interior trim, dashboards, and even in the engine bay. Their resistance to chemicals and heat makes them suitable for these demanding environments.

In electrical applications, their insulating properties make them ideal for use in electrical components and housings.

For hobbyists and DIY enthusiasts, extruded plastic rods are a versatile material that can be used in a multitude of projects. Whether you are building a model, crafting, or making repairs, these rods offer a reliable and easy-to-use solution.

Extruded plastic rods can also be used as media for 3D printing. This opens doors for endless possibilities of 3D printed parts. There is an infinite amount of material and configuration possibilities, and all industries can benefit from it.

Feature 1: Durability and Strength

Feature 2: Versatility

Feature 3: Cost Effective

Feature 4: Lightweight

Feature 5: Chemical Resistance

Application 1: Automotive Industry

Application 2: Hospitals and Laboratories

Application 3: Electric Applications

Application 4: Hobbies and DIY