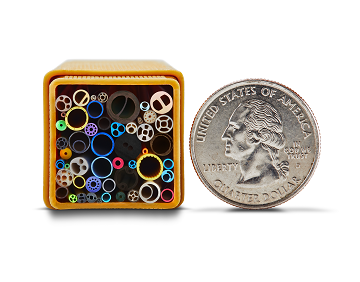

Multi Lumen Tubing

Multi lumen tubing is created as a single tube with multiple 'channels' (lumens) running throughout the inside diameter of the tube.

Dual Wall Tubing

Dual wall tubing is an excellent choice when protection from water is critical and our engineers will work with you to determine precisely the right material for both the inner and outer walls.

Micro Extrusions

Micro extrusions are one of our specialties and can be manufactured to your exact tolerance requirements.

PVC Tubing

Our Clear Plastic Tubing range from standard to custom components with wall thicknesses from thin tubing to heavy tubing.

Polypropylene Tubing

Polypropylene is a lightweight thermoplastic resin that has strong chemical resistance, dimensional stability, and excellent surface rigidity.

Polyethylene Tubing

Polyethylene can be used for clear plastic tubing as well as colored and it can be manufactured to almost any shape and size.

Reeled Flexible Tubing

Dual wall tubing is an excellent choice when protection from water is critical and our engineers will work with you to determine precisely the right material for both the inner and outer walls.

Extruded Profiles

Extruded Plastic Profiles offer a solution for industrial and electronic packaging in creating rigid, moisture resistant protective tubing.

Stripe Tubing

Our Custom Plastic Tubing catalogue of products includes single and double lumen tubing; extruded bead; striped and dual-walled tubing; multi-bore and multi-colored ribbon tubing.

Custom Plastic Tubing

Our Custom Plastic Tubing catalogue of products includes single and double lumen tubing; extruded bead; striped and dual-walled tubing; multi-bore and multi-colored ribbon tubing.

With over 30 years of experience in the Custom Extrusion Industry, A.P. Extrusion will fulfill your Custom Extrusion needs with ease.

With over 30 years of experience in the Custom Extrusion Industry, A.P. Extrusion will fulfill your Custom Extrusion needs with ease.

A.P. Extrusion has been a leader in the extruded medical tubing industry for over 30 years. Our experienced staff and state-of-the-art facility allows A.P. Extrusion to extrude your custom medical tubing from a wide range of materials; polymers, thermoplastics and custom compounds including metal filled radiopacifies.

A.P. Extrusion has been a leader in the extruded medical tubing industry for over 30 years. Our experienced staff and state-of-the-art facility allows A.P. Extrusion to extrude your custom medical tubing from a wide range of materials; polymers, thermoplastics and custom compounds including metal filled radiopacifies.

Translate your design ideas rapidly and cost-effectively. We use In-line laser and ultrasonic technologies. Automation and SPC data collection. Best practices.

Translate your design ideas rapidly and cost-effectively. We use In-line laser and ultrasonic technologies. Automation and SPC data collection. Best practices.